Our foundry exists because of a need for this part..

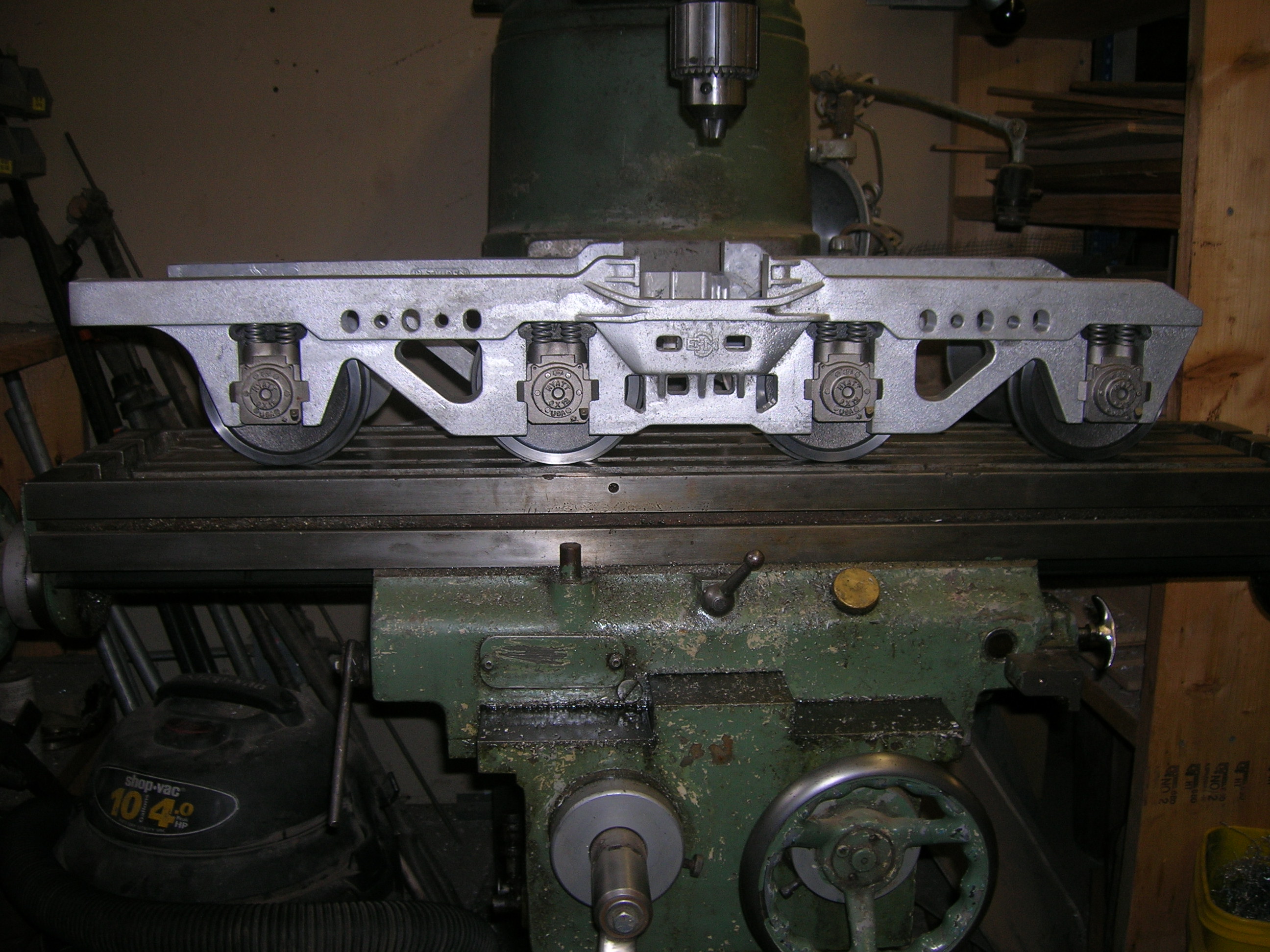

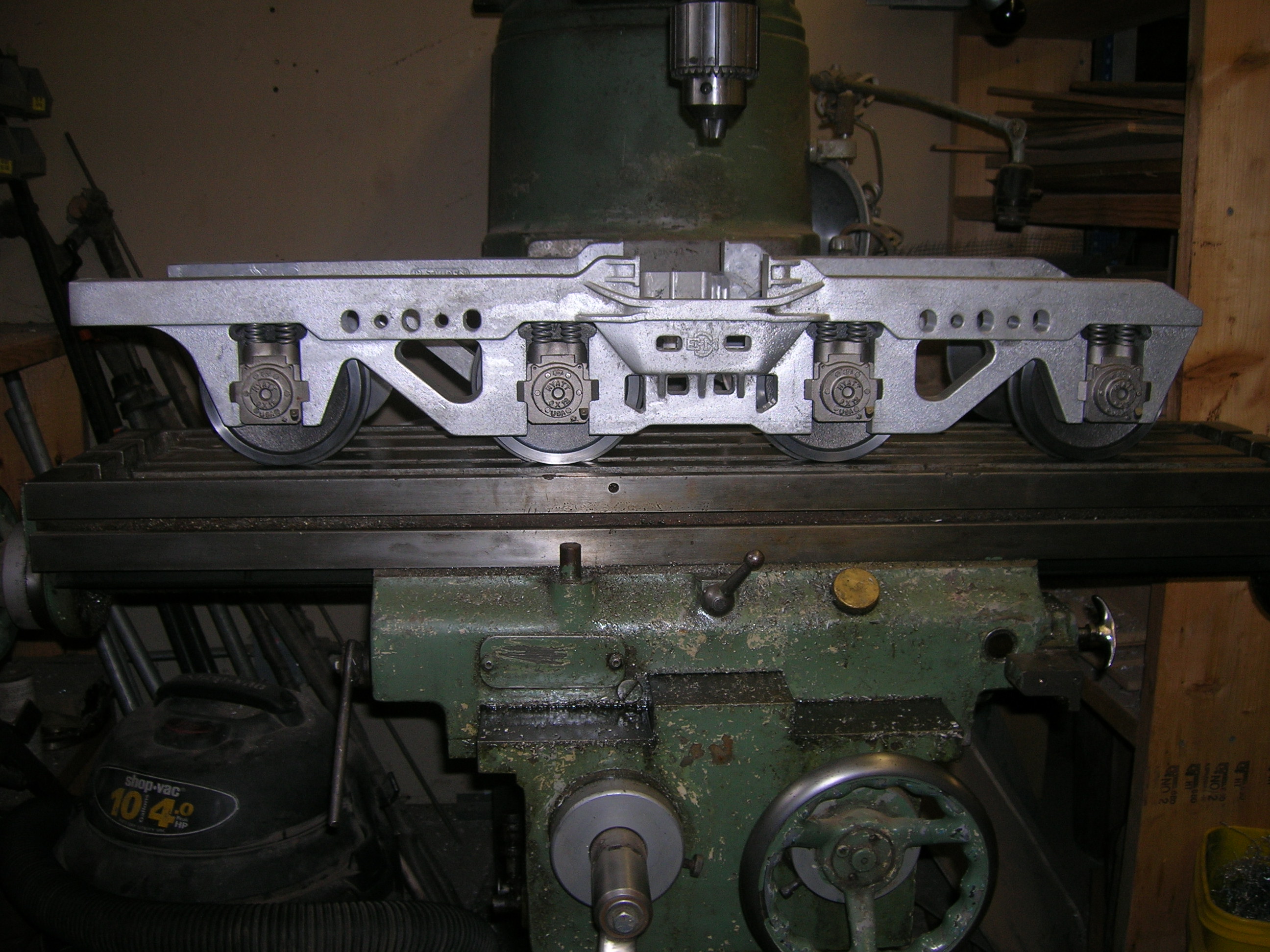

Pictured above is a one- inch- per- foot scale mockup of an EMD DD-40 wheel truck. The biggest part is the side frame assembly which carries the four axles. Initially Brian planned to machine each of the four side frames from aluminum billet stock, but after completing one part, it was apparent that he would need to start with bigger pieces of billet, that modifications would be nearly impossible after machining, and that goofs would be very expensive. It was also apparent that casting the part- and all the other parts what would be needed to make a locomotive- would be the best thing to do. The part which had already been machined was turned into a pattern by sculpting draft onto the part using epoxy putty. The part is now in its fourth revision, with the addition of several cosmetic and structural details.

Quite a change from the ready-to-close mold pictured on the other foundry page. The sand is jet black from usage and a core is now used to rough-out the spring mounts. Prior to using the core, there seemed no way to eliminate shrinkage from the thick center section. Many less noticeable details have been added, especially the small bosses to mount the actuation linkages.

Also shown in this picture is part of the muller on the right, stacks and baskets of ingots in the center, and the furnace on the left. The furnace has rubber wheels which never get hot enough to be bothered, and it is located next to a wall which lives happily behind a shielding of stainless steel and concrete board. Home-made crucible tools are on the floor. Less apparent is the blower mounted under the green hood above the furnace. The hood swings up and out-of-the-way when it is crucible time, but otherwise it funnels the heat, smoke, and fumes outside through a salvaged furnace blower. We are pouring inside because there is a fresh foot of snow on the ground and the chill factor is in the single digits.

Currently, in March 2011, these are the patterns in use. At the top is the side frame pattern, and below it, from left to right The 2-part pattern for the front and middle crossmembers, the bolster which connects the truck assembly to the locomotive chassis, a ring of brake shoes with a two-part brake cylinder pattern in the middle, and a two-part pattern for the rear crossmember. At the top of the picture are core molds for the bolster center pin and the side frame spring mounts.