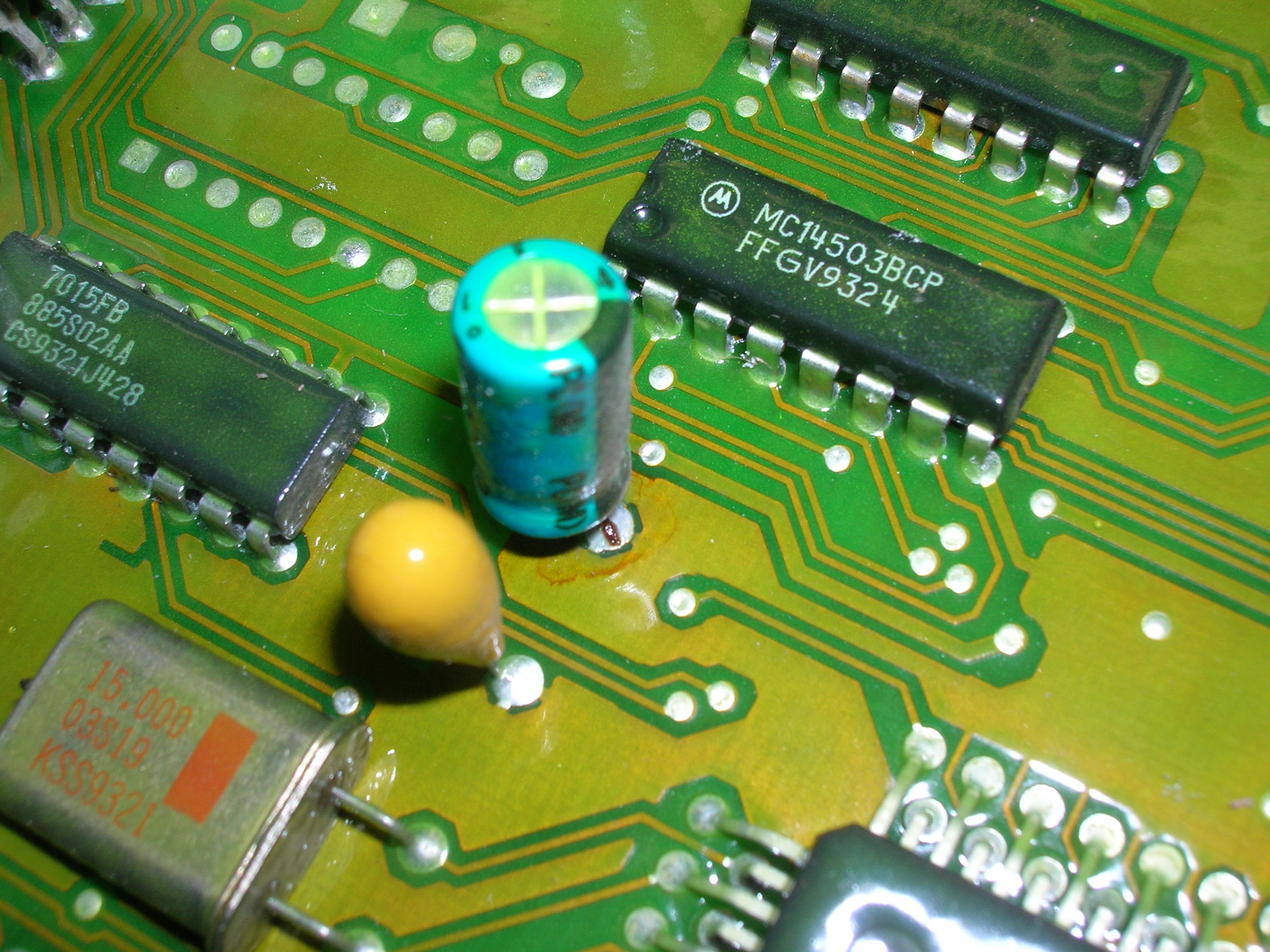

The three capacitors were obtained from Mouser Electronics for fifteen cents each (We bought thirty, because we know we will see this problem again). Brian purchased the Weller "soldering station" that he has wanted, just for this repair; a blunderbuss- type soldering iron would be a problem. Note too, that the board is sheathed with silicone, which must be scraped away prior to soldering.

On the subject of this Ford Ranger, we call it the "super Truck". We made a custom bed for it and put air bags at all four corners... with good tires and the bags, it can carry a ton and a half while looking quite innocent. It mounts a snow plow for maintaing our long driveway. At the rear we mounted a hydraulic hoist from Harbor Freight. It works "OK enough", and I use it routinely to load biodiesel materials and for sawmill logs.

Our Ranger on a muddy winter day.

Hidden under the hood is an air compressor system which is powered by the air conditioner compressor. I won't tolerate the extra clutter and maintenance of an A/C system, so we re- purposed the compressor. An oil injection port was located at the compressor inlet and an oil separator at the outlet bleeds back to the inlet. Turning the A/C on energizes it, and a pressure switch at the tank controls it.

Oh... I forgot to mention that the truck was born as a 2- wheel drive. To convert it, an Explorer front axle was fitted, and the original engine cradle crossmember was replaced with a crossmember from a 4-wd. The automatic transmission was completely disassembled so that a 4-wd tailshaft could be fitted.